The challenge

DEFINOX needed a redesign of a pigging system with a solution completely in silicone rubber where the parts were not screwed together. The new system was to include a magnet cage inside for detection during the cleaning process. It was important for DEFINOX to find a supplier, who already had rubber compounds with the required approvals – FDA, EC 1935/2004 and 3-A Sanitary Standards – as this would shorten the development process considerably.

The process

“During our initial meetings, we discussed the project goals and established the requirement specification together with the necessary actions,” says Heinz Schlup, Area Sales Manager at AVK GUMMI, and continues: “We reviewed the drawings and went through the different possibilities of our rubber solutions that had the required food compliance.”

Apart from testing the selected rubber compound internally at AVK GUMMI, DEFINOX has carried out internal bench tests as well as field tests of the pigging system at customer sites throughout the project. “The tests that we carry out are not subject to the same conditions as those of our customers,” says Sébastien Fontenit, and continues: “Therefore, it is important that the system is also tested by our customers. In this connection, we must make sure that the customer uses the system correctly. First of all, the parameters must be set to the new pig, and we need to make sure that the correct speed and pressure is applied as the lifetime of the pig will otherwise be shortened.”

The solution

Selected customers have tested the first generation of the new pigging system, so far for up to 120 km in use, which fulfils the expectations of DEFINOX.

“Already before receiving the results of the first field tests, AVK GUMMI made some further improvements of the pigging system,” says Heinz Schlup and adds: “We expect that the lifetime of the new improved version will be even longer than the lifetime achieved during the first field tests.”

Customer

DEFINOX SAS, France

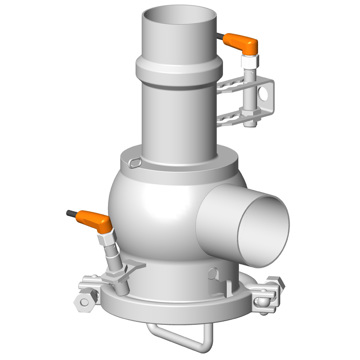

Product

Pigging system

Facts

For 50 years now, DEFINOX has specialised in the design and manufacture of valves and stainless steel equipment for industrial processes in the food, pharmaceuticals and cosmetics industries.

The DEFINOX pigging system has been part of the product portfolio for more than 20 years. This scraping system is easily adapted to various kinds of processes and is suitable for most liquid and paste products in DIN, SMS or US lines.