RUBBER COMPONENTS FOR DRINKING WATER CONTACT

AVK GUMMI develops, produces and sells rubber components for drinking water solutions with high demands on quality and know-how and with focus on regulatory compliance.

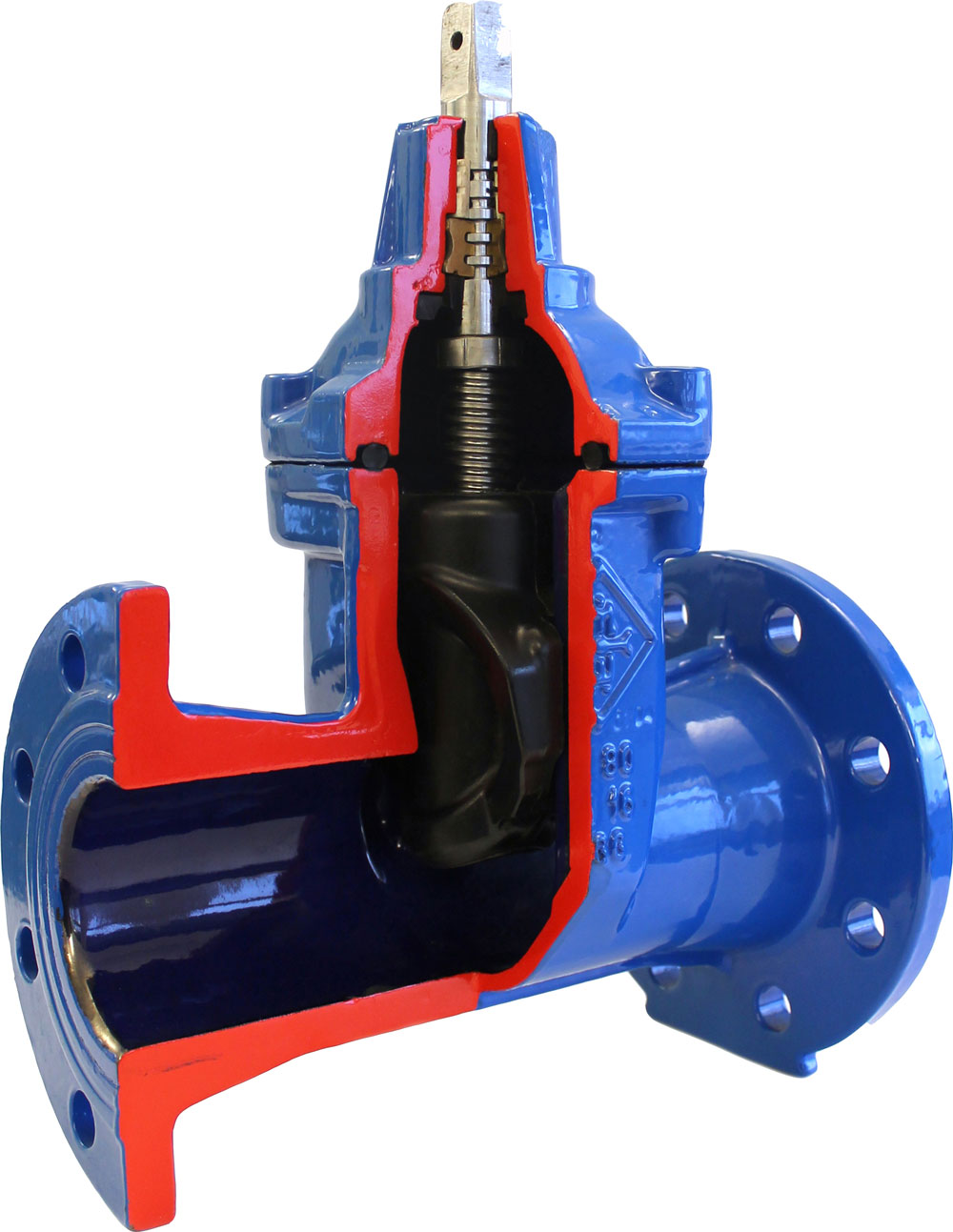

We produce customised rubber components for a wide range of applications – from the most simple products such as rubber gaskets in water taps to advanced, multiple-component liners for industrial drinking water systems.

Why our rubber solutions are suitable for contact with drinking water

Rubber components for drinking water contact are subject to enhanced requirements as a number of factors may affect the quality of the drinking water. Therefore, we have particular focus on the following factors:

- The rubber material must not affect the drinking water, e.g. by releasing taste, smell, colour or dangerous substances to the water.

Read here: How to ensure clean taste and odourless drinking water - The properties of the rubber material must provide optimal functioning, e.g. minimum permanent deformation, which ensures leak-tight gaskets. High resistance to wear, which ensures a long lifetime and low friction, enabling a low energy consumption when operating the valve.

- High resistance to chemical processes used for water treatment, such as ozonation, chlorination and chloramination.

- A low compound bio potential in order to limit the formation of biofilm.

Which type of rubber should you choose?

Although rubber only constitutes a small part of the entire drinking water system, it is of vital importance for hygiene, water waste, functionality and the final outcome; the drinking water quality. Therefore, it is important that you choose the right rubber compound for your solution.

At AVK GUMMI, we have almost 50 years of experience in developing rubber compounds and producing rubber components specifically for use in the drinking water supply. We use our experience to help you choose the right rubber quality for your product and the specific purpose.

Our R&D department continually develops new, competitive rubber compounds, which means that we always offer you gaskets and drinking water solutions that are best in class.

Read here: Drinking water system: Why the correct rubber component is essential

The primary types of rubber for drinking water in our range are:

- EPDM

- NBR

- HNBR

IPR – ownership of your rubber solution

When we develop a new compound, we use this for as many products as possible. However, if we develop a compound for you and this is critical to your business, we can enter into an exclusivity agreement.

The tool that we design for the production of your item is based on your product design and our unique tool design. You will always own IPR of the product design.

Transparency concerning the allocation of IPR is your guarantee that our collaboration will give you a competitive edge and secure your know-how.

Security of supply through advanced production

When the supply chain is challenged in a global market, you and your customers are highly dependent on your suppliers. Will you receive the products at the right time and price? And will the suppliers take responsibility for the quality of the product?

AVK GUMMI offers you security of supply in an insecure world.

We consider ourselves particularly strong within the following parts of the supply chain:

- We cooperate with large, well-reputed suppliers. Naturally, price is always an important aspect, but we must never compromise on quality, security of supply or CSR.

- We have one of the world's most advanced, fully automated mixing plants where the raw materials are weighed and dosed with the greatest precision. This enables us to manufacture rubber compounds of a uniquely high quality and uniformity.

- With production at our own factories, we can secure you traceable deliveries, no matter how the world around you evolves. At the same time, it gives you the opportunity of having a back-up production.

- We make sure that we have the right foundation for production, including the right tooling solutions. Furthermore, we always carry out a thorough validation of each manufacturing step before release for production. This is your guarantee that you always get the agreed and expected quality.

Traceability in our production

We have the tools for quickly detecting, correcting and documenting any errors in the unlikely event of an issue with your rubber component.

We collect all relevant process data throughout the entire manufacturing process. The data is stored for 25 years. Together with date marking and material identification on the parts, this forms the backbone of our traceability.

This makes it possible to locate the possible cause of the problem and at the same time imitate corrective and preventive actions.

Safety through certifications

Our certifications are your guarantee that we live up to our own high standards. We always focus on safety, quality and the environment, which means that you can fully concentrate on your product without having to spend time on supplier audits. If, however, you should to carry out an audit, you are always welcome!

At AVK GUMMI, we are convinced that focusing on quality, occupational health and the environment pays. Our quality management system is certified in accordance with ISO 9001 and IATF 16949. These systems include control of each rubber compound, full traceability with the help of our charge number system, SPC control, FMEA and an optional zero defect production.

In addition, we have an extraordinarily clean and safe production environment certified in accordance with ISO 45001. In 1991, as one of the first rubber manufacturers in the world, we obtained an environmental certification in accordance with ISO 14001.

Read here: Certifications and quality and environmental policies

Reduced loss of water – improved economy and environment

Good material properties such as high strength and minimal deformation not only improve the function of your product – whether the product be a valve, a pump or a flowmeter – but also ease the environmental impact and minimise the total costs through efficient drinking water systems with reduced water wastage and a long lifetime.

Read here: How to minimise water waste in your drinking water system

Therefore, environment, sustainability as well as your healthy bottom line are all important focus areas at AVK GUMMI. Not only for the sake of the environment, but also for the benefit of you and your customers. If we help the environment together, we can improve the bottom line – with you and your customer.

AVK GUMMI constantly sets up new targets, and our own environmental standard goes beyond that of the public authorities. This is your security that our cooperation will always give you the best possible environmental solutions tailored for the future.

Finally, we think of the environmental footprint that we leave behind. Every day, we work on reducing our energy consumption and minimising the waste. For instance, we deliver the rubber waste that we cannot entirely avoid to the local CHP plant where the waste is turned into heat and electricity. Our life cycle analysis has shown us that this is the most sustainable way of handling our rubber waste.

Consumer safety in a global perspective

If your company operates in multiple markets, you know all about the challenge of complying with the different legal requirements, recommendations and standards for products that come into contact with drinking water.

At AVK GUMMI, we manufacture rubber components for drinking water solutions based on compounds approved in most parts of the world. We send our rubber formulations to independent, accredited test institutes in a number of countries for testing and approval on an ongoing basis. This is your security that we consider local recommendations, standards and legal requirements – including compliance with lists of authorised substances and requirements concerning biofilm formation and the impact on drinking water quality.

With AVK GUMMI as your partner, you will not have to spend time looking for local suppliers that live up to your expectations. Furthermore, with rubber compounds approved for drinking water in several countries, you will have a simple product programme and your tied-up capital in stocked goods will be reduced.

Read here: Rubber compound for drinking water: Why global approvals are important

Drinking water approvals

Drinking water compounds from AVK GUMMI is your guarantee that your rubber components will not release taste or odour to the water supply, and that the drinking water will not be contaminated with foreign matters from the rubber.

With your own product design, e.g. a valve, or a gasket made of one of our compounds for contact with drinking water, you can be sure to have a fully functional product with a long lifetime.

This list shows a selection of the many standards fulfilled by rubber compounds from AVK GUMMI.

- EN 681-1

- WRAS BS 6920

- E.G./W270 (KTW-BWGL)

- ACS XP P 41-250

- AS/NZ 4020

- GB/T 5750

- SS 375

- NSF 61

- JIS K6353

- AWWA C509-94

- Ö-Norm B5014-1

- Hydrocheck

- KIWA, BRL-K602

- ASTM D6284

Product development with focus on you and your product

If you are looking for competent advice to improve your product, we are here to assist you. Often we can challenge you with new ideas that you may not have thought of. We are also happy to participate in the development of a new product right from the start – without taking over your design process.

Our focus is to transform your product requirements into concrete development parameters. This may be in the form of mechanical performance criteria, such as damping or documentation of ageing properties, to support your stability data.

With our competent advice as well as our development and production process, you and your product are in safe hands.