How to minimise water waste in your drinking water system

3% of global water resources is freshwater; the rest is salt water. 0.03% is accessible as drinking water, half of which is spread over six countries: Brazil, Canada, Colombia, Indonesia, China and Russia.

1/3 of the world’s population live in areas in which water consumption exceeds the available resources. Still, a large amount of drinking water is wasted during the transportation from the well to the tapping location because of leakages in the equipment or because of illegal water tapping. Even in highly industrialised countries, up to 20% of water is lost, while the loss in other countries can be up to 60%.

With increased water consumption, the arguments for taking good care of the water that we have should be in place. Focus must be on the choice of equipment and solutions that may help prevent leakage, enhance trouble-free operation and be in good working condition for many years. Also, it is important to have equipment that is designed to accurately measure consumption and monitor any form of leakage. Good quality pays off.

How do rubber solutions from AVK GUMMI help minimise water waste?

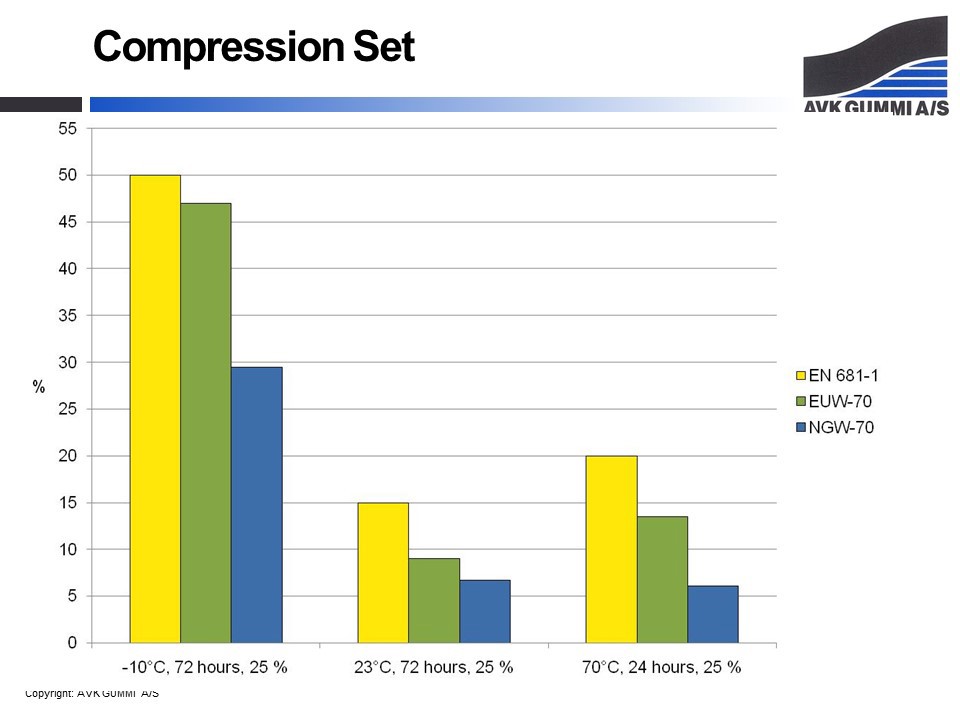

Rubber is found in many parts of the drinking water system, primarily as sealing elements. Here, the ability of the rubber compound to be deformed and return to its original shape – also called compression set – is exploited. A rubber compound with a poor compression set will gradually lose its sealing properties, which will eventually lead to leakage.

At AVK GUMMI, our compounds have been developed for the purpose and tested by independent, accredited test institutes against international standards, such as EN681. In order to live up to this standard, a good compression set at 23⁰C, 70⁰C and even -10⁰C is required.

Wear resistance is also an important factor in relation to leakage. While static components, such as flowmeters, do not require a high wear resistance, this is different for dynamic units, such as pumps and valves. If the gasket in a butterfly valve gasket is worn, the pressure towards the disc will be reduced, which will eventually result in leakage.

When AVK GUMMI develops new compounds for drinking water, we consider all the above aspects. Therefore, you can always rest assured that our rubber solutions fulfil all the requirements, which means that you can focus on the design of your product.