The transition to a PFAS-free future: New approaches in polymer technology

01.04.2025

There has been considerable debate about Per- and Polyfluorinated Alkyl Substances (PFAS) and how to avoid emission of these persistent or "forever chemicals" since the European Chemical Agency (ECHA) made the PFAS restriction proposal public in February 2023. The irreversible accumulation of PFAS, followed by the associated environmental and health risk, highlights the necessity of a broad chemical ban to stop emission of PFAS as proposed by the 5 European member states: Denmark, Germany, the Netherlands, Norway and Sweden.

Understanding the full impact of PFAS on the environment and human health is extremely complex. Similarly, predicting future legislation, including potential derogations, is equally challenging. Future legislation is still under development and will address several stages of PFAS emission, including production, manufacturing, usage and disposal.

PFAS-free solutions

AVK GUMMI A/S manufactures high performance rubber components, some of which incorporate flouoropolymers and other additives falling under the PFAS definition. However, AVK GUMMI has also decided to minimise PFAS emission in all stages of the life cycle. To meet this obligation, we must actively monitor legislative changes, including all restrictions and exemptions. Only in this way can we actively support our customers in ensuring their regulatory requirements during the transition period.

AVK GUMMI has already decided to phase out the use of all intentionally added PFAS – also outside Europe. This decision aligns not only with the anticipated EU legislation, but also with AVK GUMMI internal environmental standards that go beyond those mandated by the authorities.

Innovation through sustainable alternatives

In our production, PFAS-based mould-release agents have been successfully replaced by suitable alternatives. Additionally, alternative materials to the PFAS additive polytetrafluoroethylene (PTFE), used to reduce friction and abrasion in rubber, have been identified, tested, and are currently being qualified. Furthermore, testing of alternative film materials with high chemical and flex-resistance to replace dynamically stressed PTFE films is under way, and these alternatives are equally being qualified.

Fluoroelastomers (FKM) produced using fluorosurfactants, small and critical PFAS of significant concern, will be replaced with new FKM polymers manufactured with PFAS-free surfactants. Ultimately, these FKM rubbers will also need to be replaced with elastomers to achieve a complete phase-out of PFAS.

This critical and additional transition step is necessary due to the unavoidable emission of PFAS particles during polymer production, PFAS leachables during use and the generation of decomposition products, like perfluoroalkyl acids, during incineration. These concerns are currently under evaluation by the EU Committee for Risk Assessment (RAC).

Less than 5% of the rubber compounds manufactured at AVK GUMMI contains PFAS. As a result, AVK GUMMI already possesses the necessary expertise and competences to develop and manufacture PFAS free alternatives.

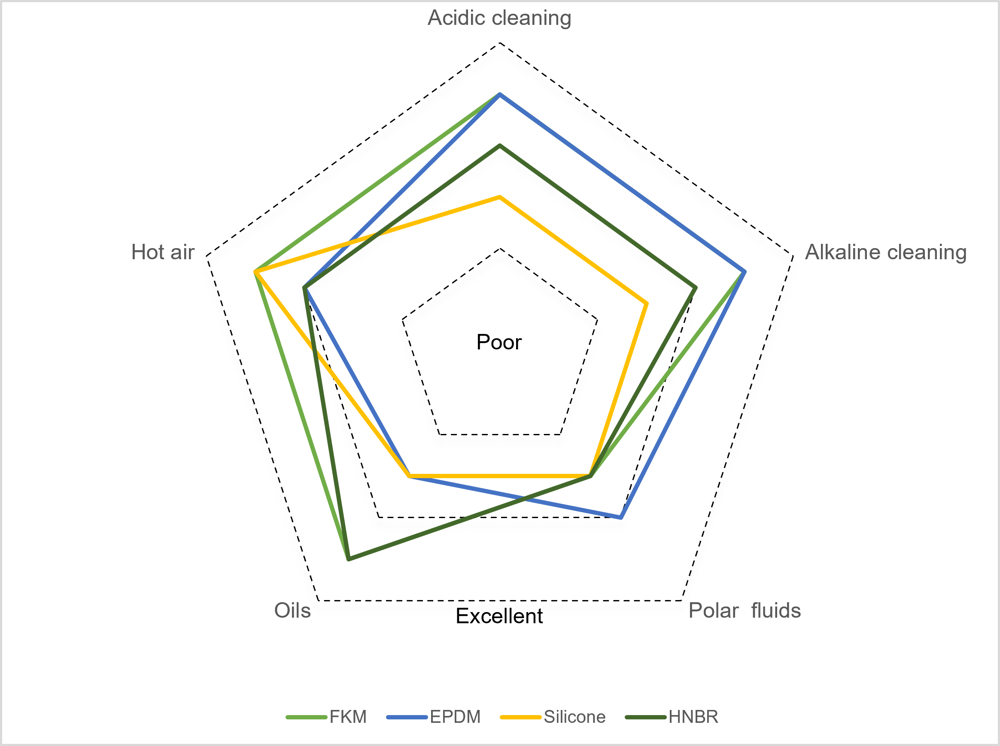

For decades, FKM has been a common choice due to its versatility as a ‘one rubber - many applications’ solution due to its broad chemical and thermal resistance compared to other rubber polymers. However, when the application and the exact exposure conditions are well-defined, AVK GUMMI can test and recommend suitable alternatives, such as specially tailored EPDM, HNBR and silicone compounds.

Collaboration with customers

Several collaborative projects have been initiated with the common goal of developing PFAS-free rubber solutions for existing FKM compounds. These projects are driven both by proactive customers and by AVK GUMMI who has urged customers to develop and execute a PFAS exit plan.

New inquiries for FKM rubber solutions thoroughly also assessed by the AVK GUMMI team, and we encourage customers to consider and explore alternative polymer types. The development process varies across projects depending on the specific application, but many initiatives already demonstrate promising insights and results. Customer applications span a wide range of industries, including food contact materials and renewal energy.

Challenges and alternatives

For food contact materials, discussion and speculation about derogations are widespread. The EU Socio-Economic Analysis Committee (SEAC) informs that derogation may be justified for specific applications but cannot be extrapolated to the entire food sector. Explicit evidence and a clear demonstration of a lack of viable alternatives are required before SEAC can support any derogations. Regardless of the final decisions, the approach from AVK GUMMI is to avoid reliance on derogations. Instead, our R&D team focus on developing and evaluating feasible alternatives in close collaboration with suppliers and customers.

Figure 1: General resistance of peroxide cured FKM, EPDM, Silicone and HNBR to typical exposures. The exposure conditions will influence the results significantly, and the chart must be considered only as a guideline.

When selecting or developing rubbers for applications with well-known use conditions, an alternative rubber polymer or a combination of polymers will, in most cases, be able to replace the required functional range covered by FKM as illustrated in figure 1. However, it is recognised that FKM exhibit chemical and temperature properties that other rubber polymers cannot achieve on their own. In such cases where a direct one-to-one performing alternative is unavailable, modifications to the component design and/or increased maintenance must be considered. AVK GUMMI aligns with SEAC in recognising that the higher cost associated with a more frequent maintenance or design modification, at least to some extent, is offset by the higher cost of FKM and therefore has no socio-economic justification.

Future-oriented approach

AVK GUMMI is not waiting for the final PFAS-restriction to enter into force but is proactively implementing a detailed exit plan for all PFAS. This decision has been made to provide customers with suitable PFAS-free rubber solutions as soon as possible since experience shows that high performance rubber materials for demanding applications require a long and thorough qualification process. AVK GUMMI is convinced that this strategy will be appreciated and accepted by customers who acknowledge the importance of transitioning to a more sustainable and healthier solution by minimising PFAS emissions.

Whether you operate in the food, energy, drinking water industry, and beyond, it might be difficult to understand and manage all the different aspects of the PFAS restrictions. Therefore, do not hesitate to contact AVK GUMMI for expert advice and assistance in selecting the right rubber solution for your specific needs.