Typical failure modes and consequence of function and safety

When choosing the right rubber compound, you must consider a number of aspects:

What are the requirements to the mechanical properties, chemical resistance, temperature, etc.? If you do not identify the right conditions from the start, there will be a risk that you will end up with the wrong polymer type or a compound that is not optimised to the conditions.

The wrong selection of rubber may cause failures either in the form of polymer degradation, swelling – and with that an increased volume – or finally permanent deformation, which will eventually lead to leakage.

Contact your rubber supplier for counselling and make sure that you have defined the correct requirements for test and documentation. That way, you will avoid any unpleasant surprises and be well prepared to give competent advice to your customers.

See below some of the major failure modes and consequences thereof:

Compression set

A phenomenon that appears when a rubber component is exposed to prolonged deformation.

When the deformation is removed, the gasket must return to its original shape to as wide an extent as possible. If that is not the case, the deformation is permanent. The consequences of this are, among, others a risk of leakage and cross contamination. Furthermore, the cleanability of the equipment will be reduced.

Chemical degradation

The wrong choice of rubber may cause accelerated degradation of the compound polymer as well as extraction of ingredients from the compound. This may cause erosion and a change of the rubber material properties, which will eventually lead to contamination of the product, leakage, cross contamination and reduced cleanability of the equipment.

Swelling

When two materials meet, a reaction will take place – either of very little importance or of a substantial character. The same applies to a rubber compound that comes into contact with food or a cleaning agent.

Volume is an extremely important property as a wrong gasket volume may obstruct the activation of the valve or prevent the valve from sealing properly. In the extreme, this may lead to the risk of equipment failures and increase the risk of leakage and reduced hygiene.

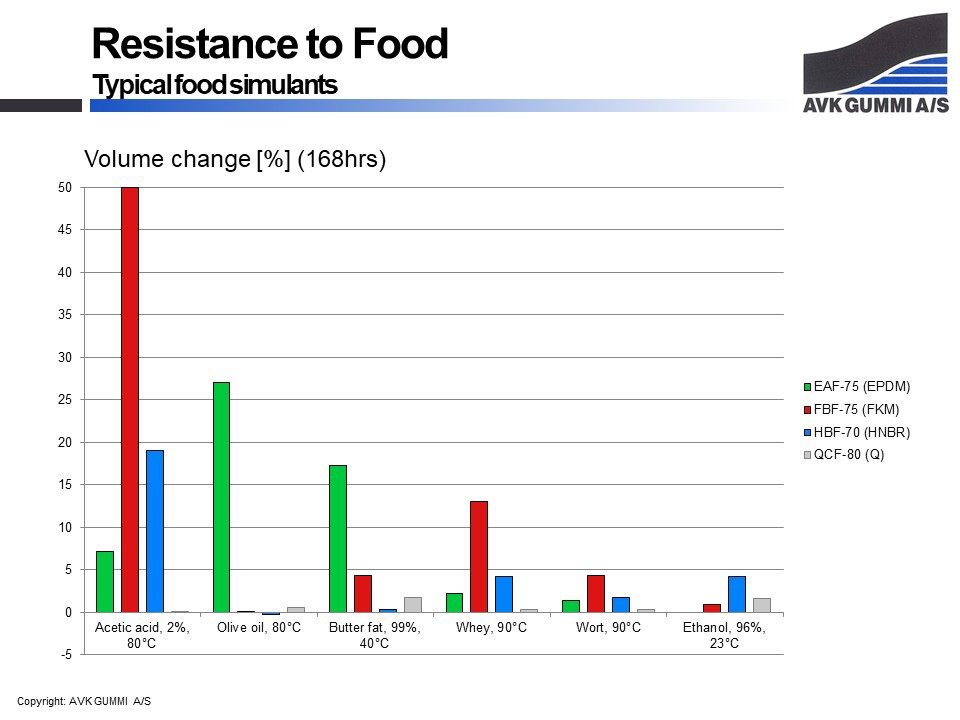

Below is an example of different rubber compounds for food contact as well as the swelling in different food simulants.

Although a 7-8% volume change is usually not critical, the aim is of course to obtain as low a swelling as possible. FBF-75, which is a fluoro compound (FKM), will swell violently in acetic acid. Clearly, this compound is not suitable for contact with acetic acid – and most other forms of carboxylic acids.

EAF-75, which is an EPDM compound, is well suited for use in polar media such as water and alcohol whereas the compound will swell severely in pure fat and oil-containing media.